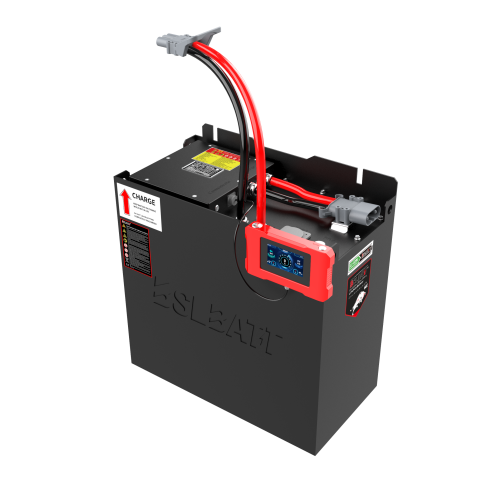

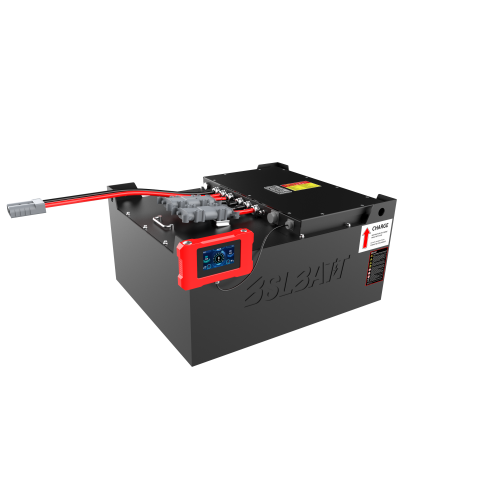

Forklift Lithium Battery

BSLBATT utilizes advanced LiFePO4 technology to produce 950 models of forklift lithium batteries ranging from 12V to 614V, which are fully compatible with various forklift brands and models. Compared with lead-acid batteries, BSLBATT lithium batteries offer longer life, higher energy efficiency and faster recharging, zero maintenance, no need to replace batteries, and remain stable and reliable even under high-intensity operation. The intelligent BMS management system ensures safe operation and helps companies save up to 70% of battery costs within 5 years, improving overall operational efficiency.

Advantages of BSLBATT®️ Lithium Batteries

- Up to 3,500+ cycle life

- Up to 10 years design life

- Drop-in Replacement

- 45-50% Lower cost than lead-acid batteries

- Cloud-based fleet management software,GPRs+GPS

- Modular architecture allows vehicle development and integration

- Eliminate the dangers of gases and acids

- For class 1-3 all-electric material handling equipment

- Fast recharge time and a 99% efficient recharge process

- Suitable for a wide range of forklift brands such as Toyota, Hyster, Crown, etc.

Why does BSLBATT®️ use LiFePO4 batteries?

BSLBATT®️ Lithium-ion Battery

| > 3500 times | Cycle Life | <500 times |

| 8 years or 12000 hours | Warranty | 3 years |

| About 1 hours | Charging Time | 8 hours |

| no memory, charge anytime | Charge Frequency | charge everytime after using |

| stable discharge condition | Low Temp . | unstable |

| 80% or more of the rated capacity at high load operation | Usable capacity | 30%-50% of the rated capacity at high load operation |

| Save > 50% in 5 years | Cost of using | High cost |

| No maintenance | Maintenance | Frequent maintenance |

| Multiple built-in protections | Safety | Risk of explosion |

Traditional Lead-Acid Battery

Multiple Applications

Class I: Electric Motor Rider Trucks

- Counterbalanced Forklifts – These forklifts can handle a capacity of 8,000 lbs or more, making them essential when lifting heavy materials throughout a facility.

- 3-Wheel Forklifts – Similar to counterbalanced forklifts, their 3 wheel design gives them a tighter turning radius, so they are a bit more nimble, at the expense of heavier lifting capacity.

Class II: Electric Narrow Aisle Trucks

- Narrow Aisle Forklifts – Found in operations that want to maximize their storage space. This lift truck can operate in tighter spaces.

- Electric Reach Truck - Ability to extend into overhead storage areas for high storage racks and high lift requirements. Provides high lifting height and good stability.

Class III: Electric Hand Trucks or Hand/Rider Trucks

- End Riders / Center Riders – Minimal lift capabilities (i.e. lifting a pallet off the ground) used to transport materials throughout a facility.

- Wallet Pallet Jacks – Designed to move loads up to 8,000 lbs. They are commonly found in delivery trucks for efficient loading and unloading of materials.