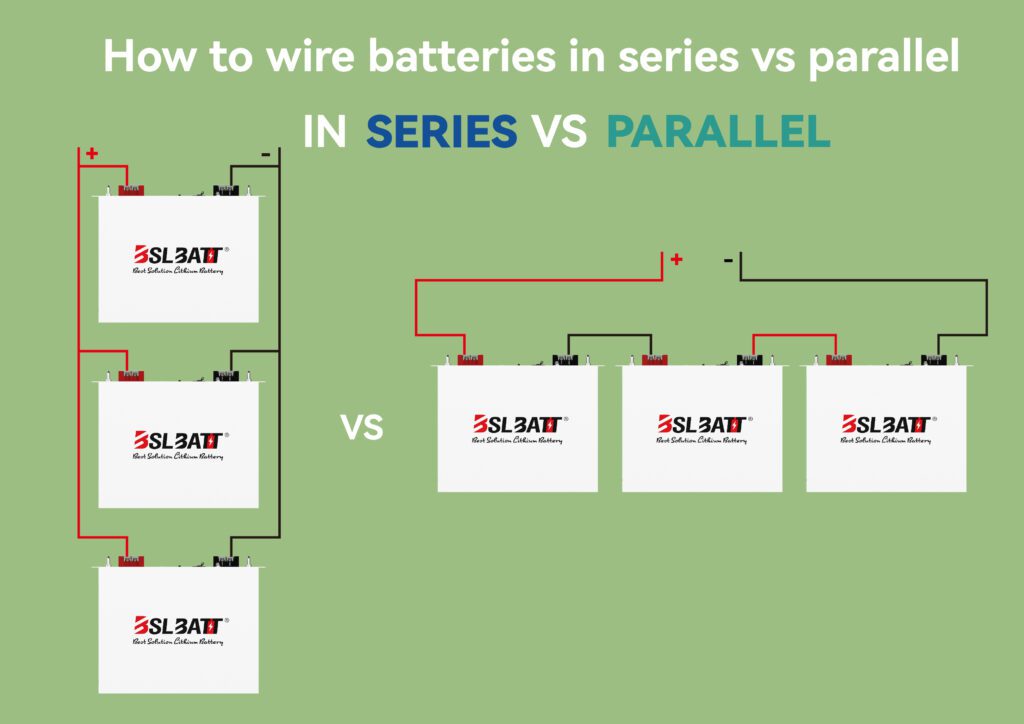

In building battery systems, the correct wiring method is crucial. Choosing between series and parallel wiring will directly affect the system’s voltage, capacity, and overall performance. Understanding these two common wiring methods will help you make an informed decision for different applications.

Understanding series vs parallel battery wiring

How series wiring increases voltage

Series wiring connects batteries in a line. The positive end of one battery connects to the negative end of the next. This setup raises the total voltage but keeps the capacity (amp-hours) the same as one battery. For example:

Four 3.6V lithium-ion batteries in series give 14.4V.

A six-cell lead-acid battery (2V per cell) makes 12V.

Two 12V batteries in series create a total of 24V.

This method works well when higher voltage is needed, like in electric cars or solar systems. Always use batteries with the same voltage and capacity to avoid problems.

How parallel wiring increases capacity

Parallel wiring connects all positive ends together and all negative ends together. This setup increases the total capacity (amp-hours) but keeps the voltage the same as one battery. For example, two 12V batteries in parallel still give 12V, but the capacity doubles. This is useful for systems needing longer runtime, like backup power or RVs.

Parallel wiring provides steady energy for a longer time. It’s great for devices that need constant power without recharging often.

How parallel wiring increases capacity

Knowing the difference between series and parallel wiring helps you pick the right setup. Here’s a simple comparison:

Aspect

Series Wiring

Parallel Wiring

Voltage

Goes up with each battery

Stays the same as one battery

Capacity

Stays the same

Goes up with each battery

Applications

High-voltage systems

Long runtime systems

Series wiring is best for high-voltage needs. Parallel wiring is better for longer energy use. Pick the setup that fits your power needs.

How to wire batteries in series

Step-by-step guide to wiring batteries in series

Wiring batteries in series boosts the total voltage of your system. Follow these simple steps to connect them safely:

Gather tools and materials:

Get batteries with the same voltage and capacity, wires, and a multimeter.Arrange the batteries:

Place the batteries side by side with terminals easy to reach.Connect the terminals:

Link the positive terminal of one battery to the negative terminal of the next. Repeat for all batteries.Check the connections:

After connecting, you’ll have one free positive terminal and one free negative terminal. These are your system’s output.Test the voltage:

Use a multimeter to measure the total voltage. It should equal the sum of all battery voltages.

Follow these steps to wire batteries in series and get the needed voltage.

Safety tips for series wiring

Safety is very important when wiring batteries in series. Mistakes can cause overheating, short circuits, or fires. Use these tips to stay safe:

Use matching batteries:

Always use batteries with the same voltage and capacity. Mismatched batteries can cause damage or safety problems.Check connections often:

Loose or dirty connections can make heat and lower efficiency. Inspect them regularly to keep them secure.Add a Battery Management System (BMS):

A BMS helps control charging and keeps voltage and current safe. It prevents overcharging and protects your system.Follow safety rules:

Use batteries that meet safety standards to reduce risks. For example:

Safety Rule/Standard

What It Does

Why It Matters for Series Wiring

Ensures batteries follow safety laws.

Makes batteries safer for series wiring.

EU Battery Directive (2006/66/EC)

Limits harmful materials in batteries.

Promotes safer use and disposal of batteries.

Battery Management Systems (BMS)

Monitors and controls battery settings.

Prevents overcharging and keeps voltage stable.

These tips help avoid problems and keep your battery system working longer.

Example applications for series wiring

Series wiring works best for systems needing higher voltage. Here are some examples:

Electric vehicles (EVs):

EVs need high voltage to power their motors. Series wiring helps reach those levels.Solar power systems:

Solar equipment often needs higher voltage. Series wiring connects batteries to meet those needs.Power tools:

Cordless tools use series-wired batteries for strong performance.Uninterruptible Power Supplies (UPS):

UPS systems use series wiring to provide high voltage during power outages.

These examples show how series wiring is useful for high-voltage systems. Knowing the difference between series and parallel wiring helps you choose the right setup.

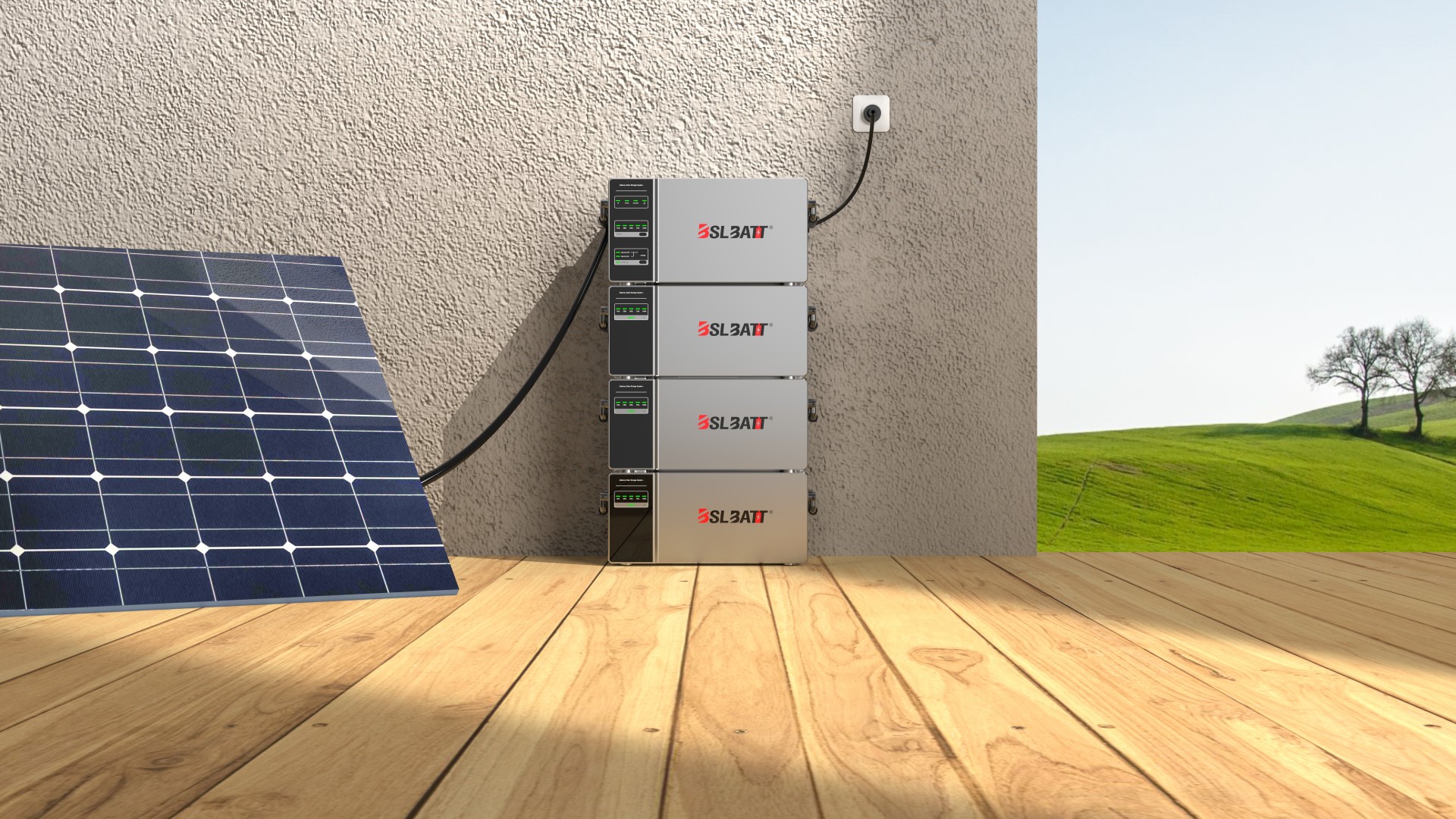

Note: BSLBATT PowerLine-5 batteries (3.2V each) can be connected in series to build a 51.2V system, suitable for home energy storage. For higher voltage applications, the BSLBATT MatchBox stackable battery supports series connections from 204.8V up to 716.8V, meeting both residential and industrial demands.

How to wire batteries in parallel

Step-by-step guide to wiring batteries in parallel

Wiring batteries in parallel boosts the total capacity (amp-hours) while keeping the same voltage. Follow these easy steps to connect batteries in parallel safely:

Gather your materials:

Collect batteries with the same voltage and capacity, wires, and a multimeter. Using different batteries can cause uneven charging and damage.Set up the batteries:

Place the batteries next to each other. Make sure the terminals are easy to reach for wiring.Link the positive terminals:

Connect the positive terminal of one battery to the positive terminal of the next. Do this for all the batteries.Link the negative terminals:

Connect the negative terminal of one battery to the negative terminal of the next. Check that all connections are tight and clean.Check the system:

Use a multimeter to measure the voltage across the positive and negative terminals. The voltage should match one battery’s voltage. For example, if each battery is 12V, the total stays 12V, but the capacity increases.

Knowing how to measure voltage and current is important for safety. Ohm’s Law helps calculate these values. Resistance checks show how parts work together in parallel setups.

Safety tips for parallel wiring

Safety is key when wiring batteries in parallel. Follow these tips to avoid problems:

Use matching batteries:

Always use batteries with the same voltage and capacity. Different batteries can cause overheating or poor performance.Check connections often:

Loose or dirty connections can cause heat and waste energy. Clean and tighten them regularly.Install a Battery Management System (BMS):

A BMS balances the charge between batteries. It prevents overcharging and keeps the system safe. This is very helpful in parallel setups where one bad battery can lower the system’s capacity.Understand safety risks:

A bad battery in parallel wiring is less harmful than in series wiring. But it still lowers the system’s capacity. Regular checks can catch problems early.

Aspect

Description

Voltage

The pack’s voltage stays at 3.60V when cells are in parallel.

Capacity

Capacity (Ah) and runtime grow four times with four cells in parallel.

Safety Consideration

A bad cell in parallel lowers capacity but is less risky than in series.

Example applications for parallel wiring

Parallel wiring works well for systems needing more runtime or capacity. Here are some examples:

Backup power systems:

Parallel wiring gives longer-lasting power for UPS and emergency systems.Recreational vehicles (RVs):

RVs use parallel wiring to run devices and appliances for longer without recharging.Solar energy storage:

Solar systems store more energy with parallel wiring. They provide steady power during cloudy days or at night.Industrial uses:

Parallel wiring is used in power lines and electrical systems to improve capacity and reliability. For example, in Algeria, a power line used parallel single-core cables. Tests showed it worked well in short circuit situations.

Note: The BSLBATT B-LFP48-100E is a 51.2V, 100Ah lithium battery with a 5kWh capacity. This model supports parallel connections of up to 63 identical modules within a single rack. When connected in parallel, the total system capacity can be expanded to 315kWh, which is suitable for both residential energy storage (for large homes or small communities) and commercial or industrial applications that require high-capacity storage solutions.

Series vs parallel: Picking the right wiring method

When to use series wiring

Choose series wiring when you need higher voltage for your system. This setup works well for devices needing more power to run smoothly. For example:

Electric cars use series wiring to power their motors.

Solar systems use it to meet inverter voltage needs.

Series wiring is great for tools and machines needing strong power. Adding more batteries increases voltage, making it ideal for high-performance setups. Always use batteries with matching voltage and capacity to avoid damage.

When to use parallel wiring

Pick parallel wiring when you need longer runtime or more capacity. This setup is common in backup power systems like UPS, which need extended operation during outages. RVs also use parallel wiring to run appliances longer without recharging often.

Parallel wiring is reliable because each part works on its own. For example:

In LED panels, if one fails, others keep working.

This setup is scalable, letting you add batteries or parts easily without big changes.

Combining series and parallel wiring for advanced setups

Sometimes, combining series and parallel wiring gives the best results. This hybrid setup boosts both voltage and capacity, perfect for large solar systems or industrial machines. For example:

Connect series-wired battery groups in parallel for better performance.

Managing these setups needs careful planning. Problems like uneven battery resistance or heat differences can lower efficiency. Studies show mismatched batteries can shorten life by 40%. Big temperature differences can speed up battery wear. Use a Battery Management System (BMS) to balance and protect the system.

By knowing the benefits of each wiring type, you can pick the best setup or combine them for advanced uses.

Comparison table: Series vs parallel battery wiring

Voltage and capacity differences

Knowing how voltage and capacity change in series and parallel wiring helps you pick the right setup. In series wiring, the total voltage adds up from all batteries, but the capacity stays the same. For example, three 12V batteries in series give 36V total, but the capacity matches just one battery. This setup works well for systems needing high voltage.

Parallel wiring keeps the voltage the same as one battery but increases the capacity. The current from each battery combines to boost the total capacity. For instance, three 12V batteries in parallel still give 12V, but the capacity triples. This setup is great for systems needing longer runtime or more energy storage.

Advantages and disadvantages of each method

Both wiring methods have pros and cons. Here’s a simple comparison:

| Wiring Type | Voltage | Capacity | Use Case | Pros | Cons |

|---|---|---|---|---|---|

| Series | ↑ | – | High power | Efficient voltage | Single cell failure impacts all |

| Parallel | – | ↑ | Long runtime | Redundancy | Heavier cable load |

Choose the method that fits your system’s needs. Series wiring is best for high voltage, while parallel wiring works better for longer runtimes.