As experts in lithium-ion batteries, particularly in the realm of lithium iron phosphate batteries, we understand the importance of proper charging protocols. Many individuals, especially those encountering such batteries for the first time, often express concerns regarding the correct charging procedures for lithium iron phosphate batteries.

As a leading manufacturer and supplier of LiFePO4 batteries, we are here to provide comprehensive guidance on this matter. In this article, we will delve into the specifics of charging BSLBATT lithium iron phosphate batteries, offering all the information you need to ensure optimal charging practices.

What is A Lithium Iron Phosphate Battery?

Lithium-ion batteries are divided into many different types depending on the material of the electrode, and lithium iron phosphate is one of them. Lithium iron phosphate battery, using lithium iron phosphate (LiFePO4) as the cathode material, the single rated voltage is 3.2V, charging cut-off voltage is 3.6V~3.65V.

LiFePO4 Battery Charging and Discharging Principle

The charging and discharging of any lithium-ion battery relies on the movement of lithium ions between the positive and negative electrodes. In the charging process, LiFePO4 will lose Li+ to become FePO4, and at this time, Li+ enters the electrolyte and then passes through the diaphragm, and is ultimately attached to the graphite crystals of the negative electrode.

After the lithium ion is de-embedded from the lithium iron phosphate, the lithium iron phosphate is transformed into iron phosphate.

During the discharge process, Li+ is separated from the graphite crystal again, enters the electrolyte again, passes through the diaphragm, and ultimately re-combines with FePO4 to become LiFePO4 after passing through the electrolyte.

After the lithium ion is embedded in the iron phosphate crystal, the iron phosphate is converted to lithium iron phosphate.

The Main Charging Method for LiFePO4 Battery: CC/CV

Currently, BSLBATT LiFePO4 battery charger adopts CC/CV charging method: Constant Current (CC) charging and Constant Voltage (CV) charging, the charging process starts with Constant Current charging, and then changes to Constant Voltage charging when approaching the termination voltage. This method can minimize the risk of charging, due to the automatic reduction of charging current, less gas precipitation during the charging process, short charging time, low energy consumption and high charging efficiency. Of course, the CC/CV charging method is suitable for all lithium-ion batteries, not only lithium iron phosphate.

(CC) Constant Current Charging

Suppose you have a BSLBATT Li-FePO4 battery with specification of 51.2V 100Ah, the charge cut-off voltage set by BMS is 55V, the battery is charged at 100A (charge rate of 1C) with constant current, at the beginning, the voltage of the battery rises with a large slope until the voltage of the battery is close to 55V, which is the charge cut-off voltage recommended by BSLBATT.

(CV) Constant Voltage Charging

The same is this BSLBATT lithium iron phosphate battery, when the battery voltage is close to 55V, change to 55V constant voltage charging, lithium battery current decreases gradually, the voltage does not change much, to the charging current drops to 1/10C (about 10A), it is considered to be close to full, and charging can be terminated.

How to Charge Different Types of Lithium Iron Phosphate Batteries?

Forklift LiFePO4 Battery

BSLBATT is a global leader in manufacturing LiFePO4 batteries for forklifts, offering comprehensive battery solutions to forklift dealerships, including charging equipment. Our charging solutions cater to the charging needs of 24V, 48V, and 80V forklift LiFePO4 batteries, encompassing various deployment scenarios such as wall-mounted and floor-standing options. Additionally, you can utilize charging equipment brands like SPE, Fronius, Delta-Q, which have established communication compatibility with our batteries, ensuring seamless charging experiences.

Golf Cart LiFePO4 Battery

There are various types of lithium-ion batteries for golf carts, ranging from 12V to 72V and beyond. Before selecting a charger, it’s crucial to carefully review the product specifications and recommendations provided by the manufacturer to ensure compatibility with the battery voltage. It’s important to note that your golf cart should be turned off before initiating the charging process.

BSLBATT offers complete LiFePO4 battery kits for golf carts, including chargers, coulomb meters/display screens, connection harnesses, and more. With our standard kits, you can directly utilize our offerings, eliminating the hassle of choosing a charger separately.

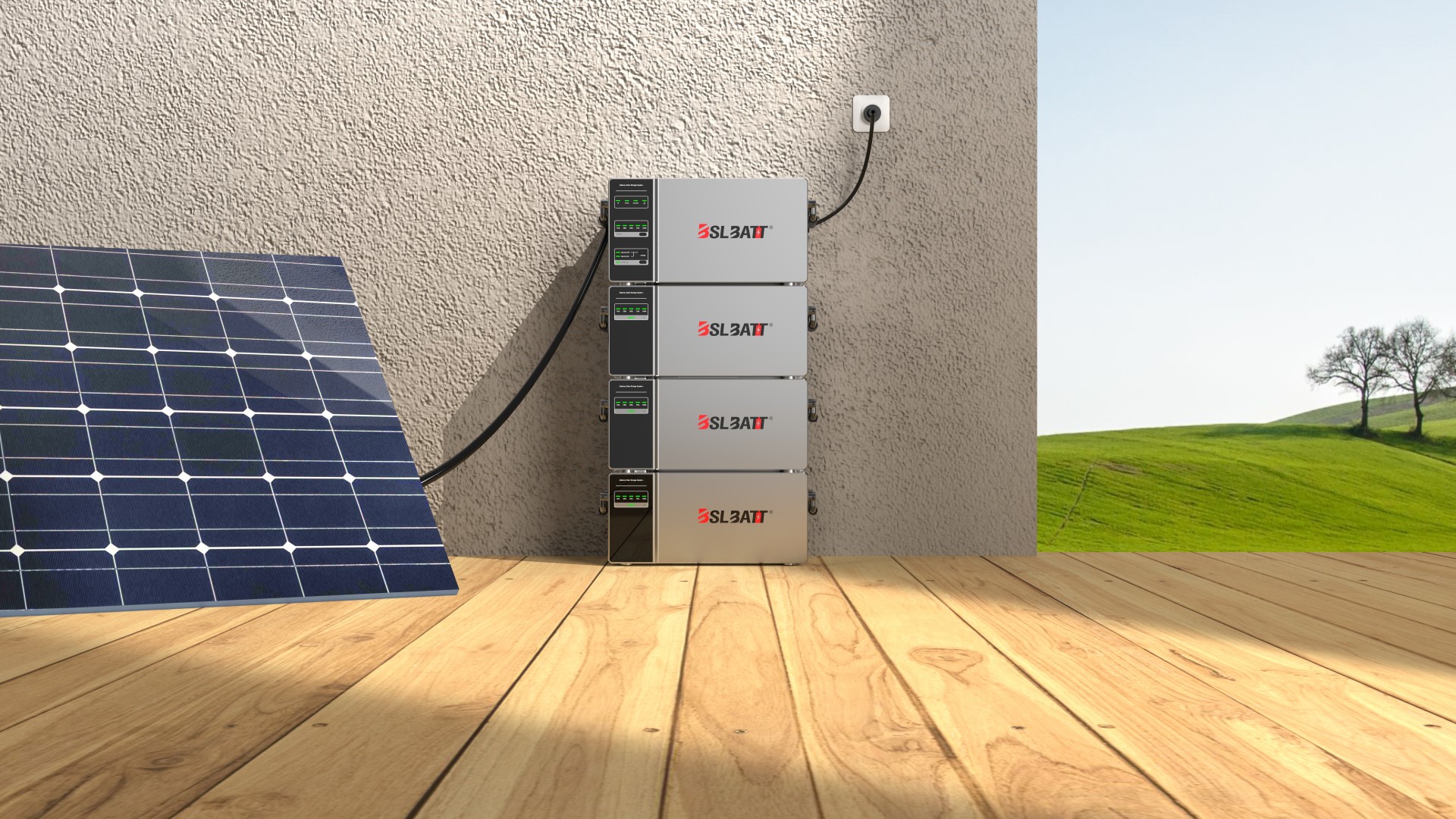

Solar LiFePO4 Battery

BSLBATT’s solar LiFePO4 batteries are currently compatible with numerous inverter brands available in the market, including Victron, Deye, Studer, Solis, Goodwe, SAJ, Afore, and more, totaling over 20 brands. You can integrate these inverters into your solar energy system to connect with BSLBATT’s solar LiFePO4 batteries. This allows you to store electricity generated from solar panels, grid power, or generators in the batteries for later use.

Charging Precautions for Lithium Iron Phosphate Batteries

Using a Lithium Battery Charger: The movement of lithium ions during the charge and discharge process, along with the characteristics of secondary chemical reactions in the battery, necessitates the use of a dedicated charger for stable charging of lithium batteries. Compared to other types of chargers, lithium battery chargers have the following notable features:

- Fast Charging: Lithium battery chargers enable rapid charging, saving time.

- Reversibility: Lithium battery chargers are reversible, preventing situations such as overcharging and over-discharging.

- Safety: Lithium batteries offer high safety standards due to built-in protection mechanisms against short circuits, overcurrent, overheating, and overvoltage.

Monitor Battery Charging Status: Overcharging lithium iron phosphate batteries would be an incorrect choice, potentially leading to battery damage or even explosions. Therefore, it’s essential to select the correct charger and monitor the charging and discharging cycles. Remove the charging equipment when the lithium iron phosphate battery is almost fully charged.

Control Charging Temperature: Charge your batteries in an environment with a temperature within the recommended range of 0°C to 45°C. Within this temperature range, lithium batteries exhibit optimal charging efficiency and speed while minimizing the impact on battery lifespan and safety. Charging at temperatures either too high or too low can severely affect battery lifespan and safety.

Conclusion

Lithium iron phosphate batteries offer numerous advantages such as high energy density, excellent safety performance, and long cycle life, making them pivotal in industrial applications such as new energy vehicles, backup power systems, and energy storage markets. Therefore, understanding how to charge lithium iron phosphate batteries is crucial for optimal battery performance and prolonging battery lifespan.

During usage, adhere to the manufacturer’s recommendations and employ the appropriate chargers and charging methods to ensure your lithium iron phosphate batteries can unleash their full potential.

If you have any further inquiries regarding lithium iron phosphate batteries, please don’t hesitate to reach out to us. Our team of professional engineers is readily available to assist you with any questions or concerns you may have. Explore BSLBATT’s lithium iron phosphate battery products and solutions with confidence.