When you choose a 48v forklift battery, you make a direct impact on your forklift’s safety and efficiency. Matching the correct battery weight and type helps prevent tip-over risks and ensures compliance with OSHA standards. Take a look at how battery types differ:

Battery Type | Weight Range (lbs) | Energy Density (Wh/kg) | Typical Lifespan (cycles) |

|---|---|---|---|

Lead-Acid | 1,200 – 2,500 | 30 – 50 | 1,000 |

Lithium-Ion | 800 – 1,800 | 150 – 200 | 3,000 |

Nickel-Cadmium | 1,000 – 2,200 | 50 – 80 | 2,000 |

You lower floor pressure and maintenance costs by choosing a forklift lithium battery. Leading lithium battery manufacturer BSLBATT delivers advanced solutions for material handling needs.

48V Forklift Battery Compatibility

Voltage Match

You need to match the battery voltage to your forklift’s requirements. Most large electric forklifts use a 48v forklift battery. Using the wrong voltage can cause electrical problems or even damage your equipment. The table below shows which battery voltages fit different types of equipment:

Battery Voltage (Volts) | Typical Equipment Types |

|---|---|

24 V | Smaller electric lift equipment (walkie pallet jacks) |

36 V | Mid-sized electric equipment (narrow aisle forklifts) |

48 V | Large electric forklifts (counterbalanced) |

80 V | Heavy-duty equipment (airport ground support) |

Always check your forklift’s manual to confirm the correct voltage.

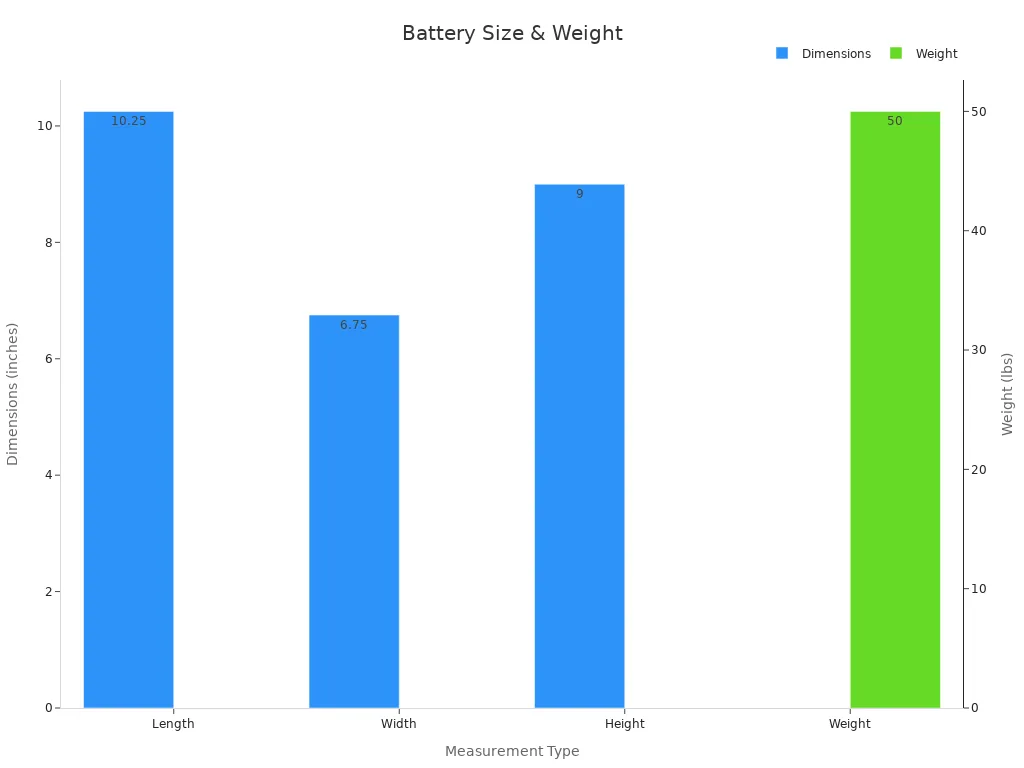

Size and Fit

A 48v forklift battery must fit perfectly in your forklift’s battery compartment. Measure the length, width, and height of the compartment before you buy. Battery Council International (BCI) standards help you find the right size. If the battery is too big or too small, it can cause poor connections or even damage the forklift. The chart below shows typical battery dimensions and weight:

Weight and Balance

The weight of your 48v forklift battery is important for safety. The battery acts as a counterweight, helping to balance the forklift when you lift heavy loads. If the battery is too light, the forklift may tip over. If it is too heavy, it can strain the forklift’s frame. Manufacturers list the recommended battery weight for each model. Always match the battery weight to your forklift’s needs.

Connector Type

You also need to check the connector type. The battery must connect securely to your forklift’s electrical system. Different brands use different connectors, so make sure the battery’s connector matches your forklift’s plug. A proper connection ensures safe charging and smooth operation.

Battery Technology

Lead-Acid vs. Lithium-Ion

When you compare lead-acid and lithium-ion batteries, you see clear differences in performance and maintenance. Lead-acid batteries have been around for decades. They require regular water refills and careful charging. Lithium-ion batteries, on the other hand, offer a modern solution with less hassle.

Here is a quick comparison:

Metric | Lead-Acid Battery | Lithium-Ion Battery |

|---|---|---|

Cycle Life | 1,500 – 2,000 cycles | 3,000 – 5,000 cycles |

Charging Speed | Slow, no fast charging | 2-3 times faster charging |

Operating Runtime | 6 – 8 hours | 8 – 12 hours |

Maintenance | Requires water refilling | Maintenance-free |

Weight | Heavier | About 50% lighter |

Total Cost (10 yrs) | Higher operational costs | 25% lower overall |

Temp. Sensitivity | Loses capacity in extremes | Maintains 95% capacity |

Charging Flexibility | Needs dedicated stations | Supports opportunity charging |

You spend less time charging and maintaining lithium-ion batteries. They last longer and weigh less, which makes them easier to handle. You also save money over time, even if the upfront cost is higher.

LiFePO4 Benefits

LiFePO4 (Lithium Iron Phosphate) batteries, like those from BSLBATT, take lithium-ion technology even further. You get several key advantages:

Extended cycle life: 4,000 to 8,000 cycles, often lasting 10 years or more.

Fast charging: Full recharge in 2-3 hours with AC power.

Stable voltage: Consistent performance throughout each shift.

Low self-discharge: Holds energy for long periods, even when not in use.

Superior safety: Thermal stability reduces fire and explosion risks.

Wide temperature range: Reliable operation from -20°C to 60°C.

Environmentally friendly: Lower cost and greater sustainability.

You benefit from less downtime, fewer replacements, and safer operation. BSLBATT’s LiFePO4 batteries support opportunity charging, so you can top up during breaks without harming battery life. This flexibility helps you keep your equipment running longer and more efficiently.

Capacity and Performance

Amp Hour Rating

Amp hour (Ah) rating tells you how much energy your battery can store and deliver over time. A higher amp hour rating means your forklift can run longer before needing a recharge. You should choose a battery with enough capacity to match your daily workload. Batteries with different capacities help you pick the best option for your operation and reduce downtime.

Battery Capacity (Ah) | Approximate Operating Time (Hours) |

|---|---|

600 (Small) | 4 |

800 (Medium) | 6 |

1000 (Large) | 8 |

Runtime and Usage

You need to think about how long your forklift must run between charges. The runtime depends on the amp hour rating and the current your forklift draws during use. If you carry heavier loads or travel longer distances, your forklift uses more power and the battery drains faster. You can estimate runtime with this formula:

Runtime (hours) = Battery Capacity (Ah) / Load Current (amps)

For example, a 200 Ah battery running at a 40-amp load gives you about 5 hours of use. Lithium-ion batteries often provide 8-10 hours of runtime per charge, while lead-acid batteries usually last 5-6 hours. Some forklifts use regenerative braking, which recovers energy and can extend battery life by up to 15%.

Forklift Model | Battery Type | Runtime per Charge |

|---|---|---|

Hyster E30-40HSD | Lithium-ion | 8-10 hours |

Hyster H1.50-3.5XT | Electric | 8 hours |

Temperature Impact

Temperature changes can affect how well your battery performs. Lithium-ion batteries work best between 25°C and 40°C. If the temperature drops too low, lead-acid batteries lose efficiency, but lithium-ion batteries keep working well. High temperatures can boost performance for a short time, but they also speed up battery wear. For example, raising the temperature from 77°F to 113°F can increase storage capacity by 20%, but it also doubles the rate of battery aging over 200 cycles. Good temperature control helps your battery last longer and stay safe.

Maintenance and Charging

Charging Time

Charging time affects how quickly you can return your forklift to service. Lead-acid batteries usually need about 8 hours to charge fully, plus another 8 hours to cool down. This schedule follows the 8-8-8 rule: 8 hours charging, 8 hours cooling, and 8 hours operation. Charging when the battery is between 20% and 30% state of charge helps extend its life. Fast charging can reduce downtime, but it may increase heat and shorten battery lifespan if not managed carefully. Lithium-ion batteries, such as those from BSLBATT, charge much faster. You can reach a full charge in less than 2 hours, and opportunity charging lets you top up in just 15-30 minutes during breaks. No cooling period is needed.

Battery Type | Full Charge Time | Opportunity Charge Duration | Cooling Requirement | Operational Benefit |

|---|---|---|---|---|

Lead-acid | About 8 hours + 8 hours cooling | Possible but shortens battery life | Required | Requires multiple batteries for multi-shift; longer downtime |

Lithium-ion | Less than 2 hours | 15-30 minutes | None | Supports multi-shift operations with one battery |

Charging Cycles

Charging cycles refer to the number of times you can charge and discharge a battery before its capacity drops. Lead-acid batteries last about 1,000 to 1,500 cycles, while lithium-ion batteries can last 3,000 to 5,000 cycles. Studies show that fast charging, if managed well, can extend battery life by up to 250% compared to standard charging. However, deep discharges and high temperatures speed up battery aging. For lead-acid batteries, following the 8-8-8 rule and avoiding charging above 40% or below 30% state of charge helps preserve cycles. Lithium-ion batteries handle frequent and partial charges better, making them ideal for busy operations.

Maintenance Needs

You spend more time and money maintaining lead-acid batteries. These batteries require regular watering, terminal cleaning, and monthly equalization charges. Improper watering causes most early failures. Each unit may need about 15 minutes of labor daily. You also need special infrastructure for ventilation and acid containment. In contrast, lithium-ion batteries, especially LiFePO4 models from BSLBATT, are virtually maintenance-free. Their sealed design and built-in Battery Management System (BMS) eliminate the need for watering or terminal cleaning. Over ten years, lithium batteries can cut battery-related labor costs by 83%, energy use by 62%, and battery replacements by 40% compared to lead-acid batteries.

Lead-acid batteries: daily watering, cleaning, and equalization; higher labor and infrastructure costs.

Lithium-ion batteries: no watering, no terminal cleaning, no equalization; lower maintenance and longer lifespan.

Cost and Value

Upfront vs. Lifetime Cost

When you compare battery options, you notice a big difference between upfront price and total lifetime cost. Lead-acid batteries cost less at first, usually between $2,000 and $8,000. Lithium-ion batteries cost more upfront, often $10,000 to $30,000. However, you save money over time with lithium-ion because you avoid most maintenance, watering, and replacement costs. Lithium-ion batteries last two to three times longer than lead-acid, often reaching 10 years or more. You also save on energy bills, since lithium-ion batteries use up to 30% less energy. The table below shows how these costs add up:

Cost Category | Lead-Acid Battery Costs | Lithium-Ion Battery Costs |

|---|---|---|

Upfront Purchase Price | $2,000–$8,000 | $10,000–$30,000 |

Maintenance (5 years) | $1,200–$4,000 | Near-zero |

Battery Lifespan | 4–6 years | 10+ years |

Lifetime Cost Savings | Baseline | 30–50% lower |

Financing Options

You do not have to pay the full price upfront. Many suppliers offer financing plans, leasing, or rental programs. These options help you spread out the cost and manage your cash flow. Some manufacturers and dealers also provide incentives or rebates for switching to energy-efficient batteries. Ask your supplier about current offers that can lower your initial investment.

Warranty and Support

A strong warranty protects your investment. Leading manufacturers back their batteries with warranties that cover defects and battery management system issues. You get peace of mind with service contracts, technical support, and even remote diagnostics. Companies like BSLBATT offer long-term warranties and expert help for installation, maintenance, and troubleshooting. Many brands also follow strict safety and quality standards, so you can trust their products to last. Reliable support means less downtime and more productivity for your operation.

conclusion & FAQ

Charging time affects how quickly you can return your forklift to service. Lead-acid batteries usually need about 8 hours to charge fully, plus another 8 hours to cool down. This schedule follows the 8-8-8 rule: 8 hours charging, 8 hours cooling, and 8 hours operation. Charging when the battery is between 20% and 30% state of charge helps extend its life. Fast charging can reduce downtime, but it may increase heat and shorten battery lifespan if not managed carefully. Lithium-ion batteries, such as those from BSLBATT, charge much faster. You can reach a full charge in less than 2 hours, and opportunity charging lets you top up in just 15-30 minutes during breaks. No cooling period is needed.

How do you know when to replace your forklift battery?

You should replace your battery if you notice shorter runtimes, slow lifting, or visible damage. Check for warning lights on your forklift. Regular inspections help you spot problems early.

Can you use any charger with a lithium-ion forklift battery?

You must use a charger that matches your battery’s voltage and connector type. Using the wrong charger can damage the battery or reduce its lifespan. Always follow the manufacturer’s recommendations.

What safety steps should you follow when handling forklift batteries?

Wear gloves and eye protection. Keep the area well-ventilated. Avoid metal jewelry. Always use proper lifting equipment. Follow your company’s safety guidelines to prevent accidents.

How long does a 48v forklift battery last?

A 48v forklift battery can last 8 to 10 years with proper care. Lithium-ion models often last longer than lead-acid types. Regular maintenance and correct charging extend battery life.

Can you recycle old forklift batteries?

Yes, you can recycle old forklift batteries. Many suppliers and recycling centers accept used batteries. Recycling helps protect the environment and meets local regulations.