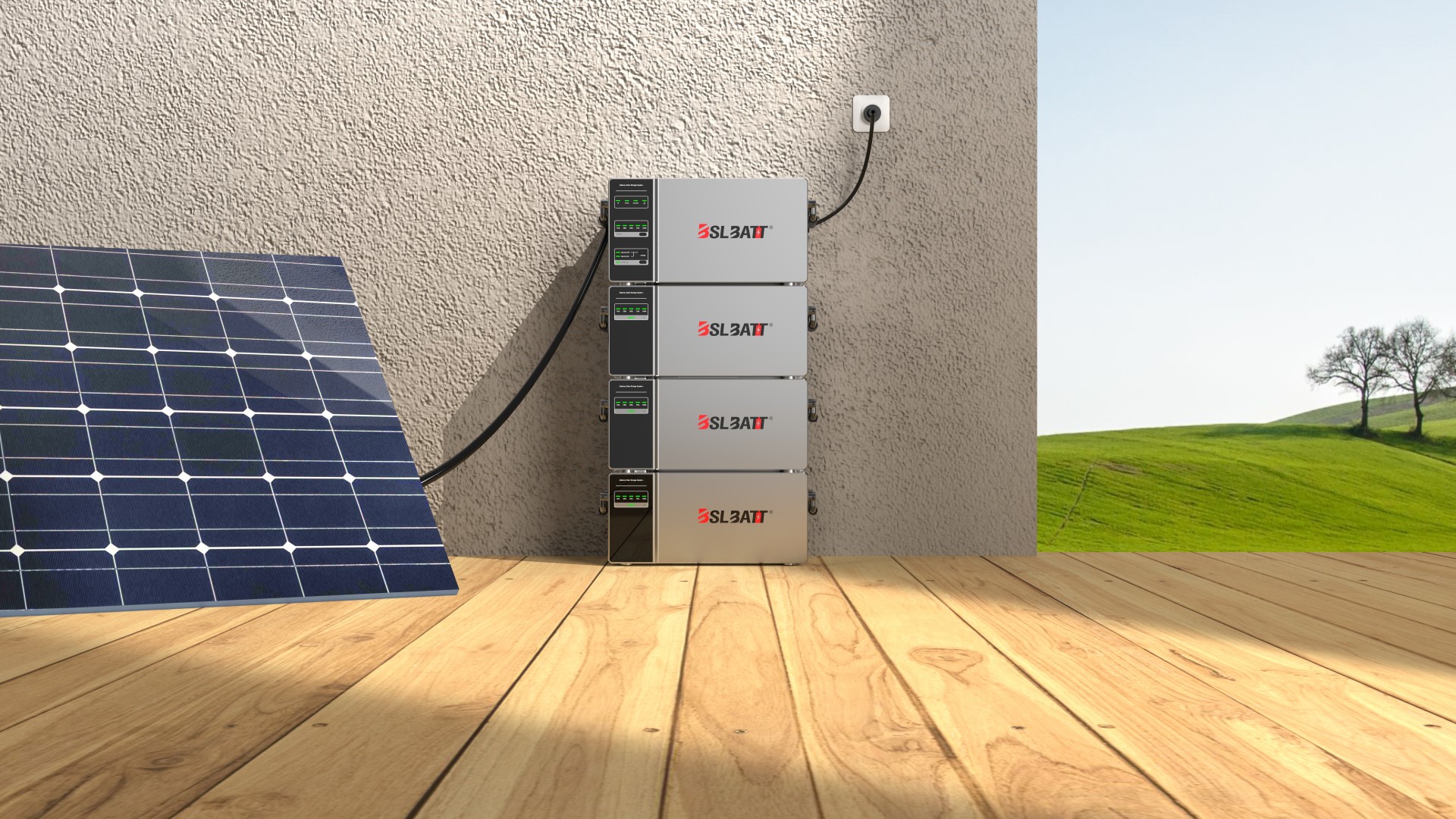

BSLBATT, a leading lithium battery manufacturer, has officially launched its 4th-generation forklift lithium battery. This upgrade brings significant improvements in materials, structural design, manufacturing, and control strategy, all aimed at solving long-standing challenges in production efficiency, product standardization, and field support.

This new generation is designed for high-performance applications and global deployment, delivering stronger compatibility, faster delivery, and lower long-term cost of ownership.

Background and Market Needs

User Feedback

The decision to upgrade the forklift battery system was based on extensive feedback from clients and industry operators. Many faced common frustrations: long lead times due to limited standardization, difficulty maintaining diverse battery configurations, and limitations in battery adaptability across different operational environments. As electric forklift adoption accelerates worldwide, customers are demanding smarter, more flexible, and more efficient power systems.

BSLBATT’s solution is built on a vision of standardization and modularity. With the introduction of a unified battery case architecture and optimized auxiliary components, the 4th-generation model reduces unnecessary custom engineering while dramatically improving installation speed and system stability. The design enables pre-built inventory, faster testing, and reduced delivery cycles, directly addressing pain points in both production and logistics.

Industry Challenges

Forklift operators in logistics and warehousing face several persistent challenges with traditional battery systems. Downtime often disrupts operations when batteries fail unexpectedly or require frequent maintenance. Many facilities struggle with a lack of standardization, leading to complicated training and increased risk of errors.

Real-time monitoring of battery voltage, temperature, and charge helps detect health issues early, but many older systems lack these features.

Predictive maintenance, such as analyzing battery data to schedule preventative actions, remains underused, resulting in unplanned downtime.

Automated alerts for battery swaps and optimized charging cycles are not standard, causing operational interruptions and reduced battery lifespan.

Maintenance routines like cleaning, fluid management, and cell balancing are often manual, increasing labor costs and the risk of mistakes.

Proper battery management reduces downtime, prevents failures, and improves safety, but many operations still rely on outdated processes.

Efficiency Demands

The logistics and warehousing industries continue to experience rapid growth, driven by e-commerce expansion and supply chain complexity. Companies now demand smarter, more efficient battery solutions to keep up with increased throughput and tighter delivery schedules.

The global demand for battery materials such as nickel, cobalt, and graphite is expected to rise by over 500% by 2030.

Battery gigafactories are multiplying, with projections showing growth from 100 in 2020 to over 300 by 2030.

Lithium iron phosphate batteries, known for their cost-effectiveness and safety, are set to make up more than 40% of EV batteries by 2030.

The smart warehousing market is projected to quadruple in value over the next decade, with automation and real-time data capture driving efficiency.

Smart Solutions

Modern battery systems now offer modular and intelligent configurations that directly address these industry needs. Modular designs allow for easy replacement and scaling, reducing downtime and simplifying maintenance.

Wireless battery management systems eliminate complex wiring, enabling automated assembly and remote diagnostics. These systems provide detailed data on each module’s state of charge and health, supporting predictive maintenance and extending battery life.

Performance assessments show that modular battery modules retain high capacity over time, allowing for reuse and supporting sustainability. Integrated data management and cloud services further optimize production and lifecycle management, ensuring that operations remain efficient and reliable even in demanding environments.

Key Technical Upgrades

Structure

The new generation features a modular PDU (Power Distribution Unit) and a standard modular case. This design allows for easy assembly, maintenance, and adaptation to different forklift models.

The modular case includes improved heat dissipation with side panel vents, keeping modules cool and extending battery life.

A new display offers a cleaner look and better user experience. The display comes with a pre-installed alarm module and a 360-degree rotating bracket for flexible viewing.

Engineers have added a fan and rain cover to the standard case. The fan can be switched on or off as needed, and the rain cover protects internal components from water and dust.

All connectors are hidden inside the case, creating a neat and professional appearance.

Manufacturing

BSLBATT has streamlined its manufacturing process by using a standard case with an external counterweight. This approach allows for mass production and faster delivery times.

The standard case can be paired with different counterweights to match various forklift requirements, without changing the core battery design.

This method reduces production costs and simplifies the supply chain.

The modular structure also makes it easier to test and stock batteries in advance, ensuring quick response to customer orders.

Advances in battery pack design, such as standardized cases and modular components, help reduce size and cost while improving safety and performance.

Control Systems

The upgraded control systems in BSLBATT Lithium Batteries offer smarter and safer operation.

The REMA charging connector now includes a temperature sensor and thermal logic. This feature prevents overheating and connector damage during charging.

Users can update battery programs externally through a USB port, without opening the case.

The system includes a one-touch range extension button. When the battery runs low, this button activates a backup reserve, allowing the forklift to return safely for charging.

External balancing options help maintain cell health and extend battery lifespan.

Built-in fire suppression and heating functions ensure safe operation in harsh environments.

The fan control button lets users adjust cooling based on climate needs.

These control upgrades provide real-time monitoring, improved safety, and easier maintenance, supporting efficient operations in logistics and warehousing.

User Feature Upgrades

Connectivity

BSLBATT Lithium Batteries deliver advanced connectivity features that simplify maintenance and enhance operational efficiency. The external USB port allows technicians to update firmware, adjust settings, and perform diagnostics without opening the battery case. This design reduces downtime and minimizes the risk of accidental damage during maintenance. Operators can connect laptops or diagnostic tools directly to the battery, enabling real-time monitoring and troubleshooting.

The system also supports external balancing. This function allows technicians to balance individual cells from outside the battery pack, which helps maintain optimal performance and extends the overall lifespan of the battery.

Key connectivity features include:

USB port for program updates and diagnostics

Real-time data monitoring and event logging

External cell balancing for improved efficiency

Safety

Safety remains a top priority in the design of BSLBATT Lithium Batteries. The battery pack includes a built-in fire extinguisher, providing an extra layer of protection in the rare event of thermal runaway or internal failure. The system also features a one-touch emergency return function. When the battery nears depletion, operators can activate a backup reserve, allowing the forklift to return safely to a charging station.

A temperature sensor in the REMA charging connector monitors heat levels during charging. The system automatically adjusts charging logic to prevent overheating and connector damage. The modular case design hides all connectors inside, reducing the risk of accidental contact and improving overall safety.

The combination of automated alarms, integrated fire suppression, and emergency return functions ensures that operators can respond quickly to unexpected situations, minimizing risk and downtime.

Safety highlights:

Built-in fire extinguisher for rapid response

Emergency return button for safe operation

Temperature-controlled charging to prevent overheating

Climate Adaptability

BSLBATT Lithium Batteries adapt to a wide range of environmental conditions, supporting reliable operation in both hot and cold climates. The battery pack includes a fan with an on/off control, allowing operators to manage cooling based on ambient temperature. In hot environments, the fan dissipates heat efficiently. In cold settings, users can turn off the fan and activate the built-in heating function to maintain optimal battery temperature.

Environmental testing confirms that lithium-ion batteries face challenges at low temperatures, such as reduced capacity and charging difficulties. However, BSLBATT Lithium Batteries use advanced materials and external heating strategies to overcome these issues. The system maintains stable performance and safety, even in harsh warehouse or outdoor environments.

Operators working in multi-shift or cold chain logistics benefit from these climate adaptability features. The battery supports continuous operation across shifts and seasons, reducing the need for frequent battery swaps.

Climate adaptability features:

On/off fan control for flexible cooling

Built-in heating for low-temperature operation

Reliable performance in multi-shift and cold chain environments

Standardization and Cost updates

Design

BSLBATT engineers have prioritized a consistent internal layout for their fourth-generation lithium forklift batteries. This approach streamlines assembly and simplifies maintenance. Each battery uses a modular case with standardized internal partitions and optimized battery racks. The design maximizes space and improves access for technicians. Side panel vents and integrated fan systems regulate temperature, protecting battery modules from overheating.

A well-organized internal structure reduces the risk of wiring errors and speeds up routine inspections. Technicians can quickly identify and replace faulty components, minimizing downtime.

A recent project in battery energy storage systems highlights the benefits of this approach:

Aspect | Description |

|---|---|

Internal Layout | Optimized racks and partitions maximize space and improve maintenance access. |

Thermal Management | Integrated fans and airflow systems maintain safe battery temperatures. |

Manufacturing Benefits | Standardized components reduce material costs and production lead times. |

Cost Reduction Outcomes | Lower shipping and handling costs, reduced downtime, and improved operational efficiency. |

This table demonstrates how a consistent internal layout and optimized thermal structure contribute to easier maintenance and operational savings.

Cost Efficiency

Standardization allows BSLBATT to use a single battery case for multiple forklift models. By adjusting only the external counterweight, the company adapts the same core battery to different requirements. This strategy reduces the need for unique parts and simplifies inventory management.

Manufacturers benefit from mass production of standardized modules. Production lead times decrease, and material costs drop due to bulk purchasing. Shipping costs also fall because lighter, modular cases require less packaging and handling.

A concurrent design optimization framework, similar to that used by leading electric vehicle manufacturers, shows that standardizing battery modules across product families can lower the total cost of ownership by up to 17%. BSLBATT’s approach delivers similar advantages, making advanced lithium battery technology more accessible and cost-effective for global logistics and warehousing operations.

Global Operations

Global Operations

BSLBATT delivers standardized lithium battery solutions that support global logistics, warehousing, cold chain, and industrial fleets. Companies in these sectors require reliable power sources that perform consistently in demanding environments. BSLBATT meets this need by combining intelligent battery management with robust design and worldwide compatibility.

Many leading forklift manufacturers and logistics providers trust BSLBATT batteries. The company maintains a global network with manufacturing and service centers in China, the United States, the Netherlands, Turkey, South Korea, Mexico, and South Africa. This presence ensures rapid support and seamless integration for customers across continents.

BSLBATT batteries undergo rigorous testing, including overcharge, over-discharge, short circuit, drop, and extreme temperature assessments. Automated inspection systems and real-time data monitoring help maintain consistent quality. These measures have reduced battery failure rates by over 30%. Intelligent Battery Management Systems further decrease failures by up to 30% through real-time analysis and fault detection.

BSL lithium battery models, such as B-LFP48-615MH and B-LFP36-820MH, have earned certifications from UL Solutions to the latest safety standards. BSLBATT batteries also comply with IEC, CE, and UN38.3 requirements. These certifications confirm their safety and reliability in harsh industrial settings.

Certification | Description | Application Scope |

|---|---|---|

UL2580 | Battery safety for electric vehicles | Global industrial and automotive |

IEC | International safety and performance | Worldwide |

CE | European safety and environmental standards | Europe and global |

UN38.3 | Transport safety for lithium batteries | International shipping |

BSLBATT’s partnership with Underwriters Laboratories (UL) allows in-house qualification and testing. This accelerates certification and ensures compliance with strict global standards.

The global battery market continues to expand, driven by electric vehicles, industrial automation, and logistics. BSLBATT’s standardized, intelligent batteries position companies to meet these demands while maintaining safety and efficiency in every region.

conclusion & FAQ

BSLBATT Lithium Batteries deliver advanced features that drive efficiency, safety, and cost savings for forklift operations. Operators benefit from high round-trip efficiency, robust thermal management, and compliance with global safety standards. The table below highlights key advantages:

Many leading forklift manufacturers and logistics providers trust BSLBATT batteries. The company maintains a global network with manufacturing and service centers in China, the United States, the Netherlands, Turkey, South Korea, Mexico, and South Africa. This presence ensures rapid support and seamless integration for customers across continents.

Category | Feature | Benefit |

|---|---|---|

Efficiency | Less energy loss, more usable power | |

Durability | Long Cycle Life, Warranty | Extended operational lifespan |

Cost Savings | Incentives, Lower Upfront Cost | Improved affordability |

Safety | Thermal Management, Compliance | Enhanced protection and reliability |

Companies seeking reliable, future-ready power solutions should consider upgrading to BSLBATT Lithium Batteries.

What forklift brands work with BSLBATT fourth generation lithium batteries?

BSLBATT batteries support most major forklift brands. The modular design allows easy integration with models from Toyota, Hyster, Linde, Jungheinrich, and others. Compatibility ensures smooth upgrades for diverse fleets.

How does the emergency return function operate?

Operators press the emergency return button when the battery nears depletion. The system activates a backup reserve. This feature allows the forklift to travel at low speed back to the charging station safely.

Can technicians update battery software without opening the case?

Yes. The external USB port enables technicians to update firmware and run diagnostics directly. This design reduces downtime and prevents accidental damage during maintenance.

Are BSLBATT lithium batteries safe for cold storage environments?

BSLBATT batteries include built-in heating and advanced thermal management. These features maintain performance in cold storage and outdoor settings. The system adapts to temperature changes, supporting reliable operation year-round.